Metal Castings: Choosing Between Sand, Die, or Investment Casting

Discover the Convenience of Light Weight Aluminum Castings: Necessary Realities and Providers You Need To Know

Light weight aluminum castings are increasingly identified for their versatility across different fields. Their light-weight nature, deterioration resistance, and strength-to-weight ratio make them a preferred choice in numerous applications. From automotive to aerospace, the versatility of these castings is remarkable. The techniques of manufacturing and the variety of solutions readily available commonly go unnoticed. Recognizing these facets can substantially affect project results and effectiveness. What necessary facts and services should one think about when exploring aluminum spreadings?

The Characteristic That Make Light Weight Aluminum Castings Ideal for Various Industries

Light weight aluminum castings possess a distinct mix of residential or commercial properties that provide them extremely appropriate for a wide variety of markets. Their light-weight nature is one of the most substantial benefits, permitting simpler handling and minimized transportation costs (Aluminum Castings). Aluminum castings also exhibit exceptional deterioration resistance, which prolongs the lifespan of components in difficult settings. Furthermore, they use good thermal and electrical conductivity, making them perfect for applications needing reliable heat dissipation or electrical connections

Typical Applications of Aluminum Castings

In addition, the electrical sector frequently uses light weight aluminum castings for rooms and housings, facilitating reliable heat dissipation and boosting safety. The durable goods sector uses light weight aluminum castings in products such as cookware and furnishings, where appearances and performance are vital.

The aquatic market depends on aluminum castings for parts that endure rough environments, such as boat hulls and installations. Generally, aluminum castings serve a wide range of functions, showcasing their flexibility and necessary role in modern manufacturing processes.

Various Casting Approaches Discussed

Comprehending the different casting approaches is essential for selecting the suitable strategy for light weight aluminum spreadings. 2 prominent methods, sand spreading and pass away spreading, deal distinctive benefits and applications. Each method's special qualities influence the end product's quality and suitability for specific usages.

Sand Spreading Process

While various casting approaches exist, sand spreading continues to be among one of the most widely made use of strategies as a result of its adaptability and cost-effectiveness. This process involves producing a mold from a mixture of sand and a binding agent, which develops the cavity into which molten aluminum is poured. The sand mold can be easily shaped and recycled, permitting the manufacturing of complex geometries. As soon as the light weight aluminum solidifies, the mold and mildew is escaped, revealing the actors component. Sand spreading is specifically suitable for low to medium production volumes, making it perfect for personalized components. Its versatility to various shapes and sizes, paired with the ability to suit intricate layouts, further enhances its appeal in various markets.

Die Spreading Techniques

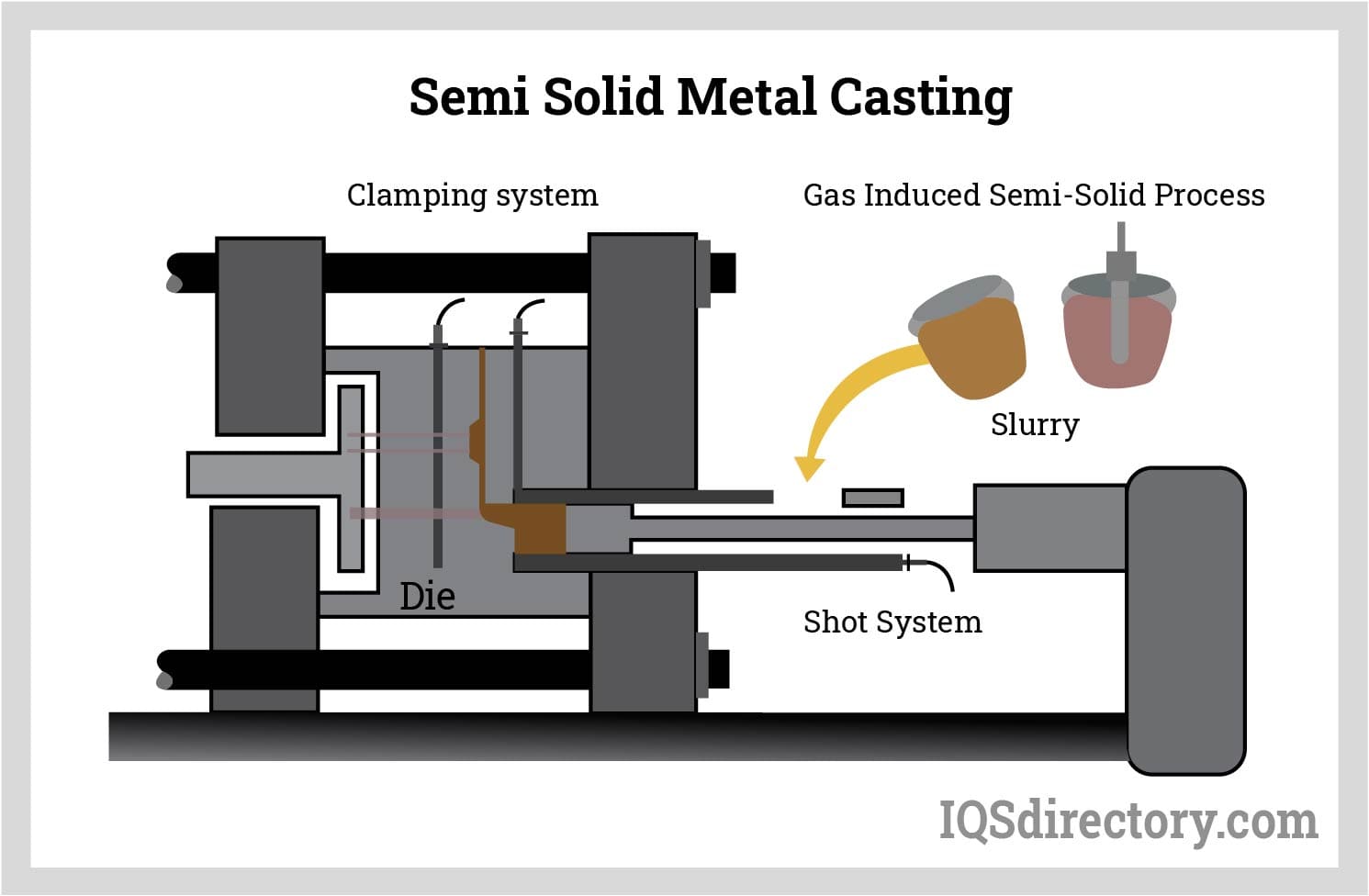

Die casting stands for a distinct approach in the area of light weight aluminum spreading methods, offering high accuracy and effectiveness for automation. This technique involves requiring molten aluminum right into a mold under high pressure, guaranteeing a important site top notch surface and tight tolerances. There are two primary kinds of die casting: warm chamber and cold chamber. Warm chamber die casting is suitable for low melting factor alloys and permits for rapid manufacturing cycles. On the other hand, cool chamber pass away spreading is made use of for materials with higher melting factors, calling for the light weight aluminum to be ladled right into the chamber. Both strategies make it possible for the production of complex forms and intricate designs, making die casting a favored option for markets such as auto, aerospace, and consumer items.

Benefits of Utilizing Aluminum Castings

Countless benefits make aluminum spreadings a favored selection throughout numerous industries. To begin with, aluminum's light-weight nature significantly decreases the general weight of products, boosting their efficiency and performance. Furthermore, light weight aluminum castings exhibit exceptional rust resistance, which prolongs item life-span and lowers maintenance prices. The material's high thermal and electrical conductivity also makes it perfect for applications in automobile and electronics markets.

Furthermore, light weight aluminum castings can be created with intricate layouts, allowing suppliers to produce complicated forms that satisfy particular requirements. This versatility not just sustains innovative designs yet also lowers the demand for added machining procedures, conserving time and resources. Aluminum's recyclability straightens with sustainability goals, appealing to ecologically mindful organizations. Collectively, these advantages setting aluminum spreadings as a remarkable remedy for a variety of applications, ensuring toughness, effectiveness, and cost-effectiveness in today's open market.

Providers Offered by Light Weight Aluminum Casting Manufacturers

Additionally, they normally give different casting methods, such as sand spreading, pass away spreading, and financial investment casting, each fit for different task needs. Quality control is another important service, with suppliers carrying out rigorous screening and examination protocols to guarantee that spreadings meet market great site criteria.

Aluminum spreading business frequently help with ending up services, including machining, surface area therapy, and finishing, improving the final item's toughness and visual appeal. They may offer logistical assistance, assuring prompt shipment and effective supply chain administration to meet customer deadlines.

Tips for Picking the Right Light Weight Aluminum Spreading Companion

Selecting the right light weight aluminum casting partner can significantly affect the success of a project (Aluminum Foundry). To ensure compatibility, companies need to initially analyze the companion's market experience and technical competence. A carrier with a strong history in details applications can offer valuable insights and cutting-edge remedies

Next, it is important to examine the quality assurance processes in location. A reputable partner will certainly abide by strict top quality standards and supply qualifications where relevant. Furthermore, evaluating past tasks and client endorsements can provide a more clear understanding of the companion's capacities and reliability.

Cost-effectiveness is additionally vital; nonetheless, it must not compromise top quality. Business must look for a balance in between price and the level of solution given. Open interaction and responsiveness are crucial characteristics. A companion that prioritizes collaboration promotes an effective working relationship, ultimately causing successful project end results.

Regularly Asked Inquiries

Can Aluminum Castings Be Repaired if Damaged?

Yes, aluminum castings can be fixed if damaged. Metal Castings. Methods such as welding, brazing, or glue bonding are frequently utilized, relying on the degree of the damage and the particular requirements of the fixing process

Just How Do Aluminum Castings Compare to Other Steels?

Aluminum spreadings are lighter, corrosion-resistant, and extra flexible contrasted to various other metals like steel or iron. Their excellent thermal conductivity and recyclability make them a recommended selection in numerous sectors, enhancing adaptability and efficiency.

What Is the Life Expectancy of Light Weight Aluminum Castings?

The life-span of light weight aluminum castings typically varies from 10 to 50 years, depending on ecological problems, alloy composition, and application. Correct upkeep and safety actions can greatly enhance their sturdiness and durability in various setups.

Are Aluminum Castings Recyclable?

Yes, light weight aluminum spreadings are recyclable. They can be thawed down and repurposed without shedding their inherent homes, making them an ecologically pleasant option. This recycling process adds to sustainability and minimizes the demand for brand-new aluminum production.

Exactly how Do I Keep Light Weight Aluminum Castings?

To preserve aluminum spreadings, one ought to consistently clean them to eliminate dust and oxidation, apply safety finishes to stop rust, and inspect for damages to ensure longevity and architectural honesty in different applications.

The convenience of aluminum castings allows their widespread use throughout various sectors. Recognizing the various casting techniques is vital for selecting the proper strategy for light weight aluminum castings. Pass away casting represents an unique method in the area of aluminum casting methods, supplying high accuracy and effectiveness for mass manufacturing. Countless benefits make aluminum castings a favored selection across numerous industries. Additionally, they generally provide different casting methods, such as sand casting, pass away spreading, and investment spreading, each matched for different project needs.